Life in harmony with nature

Wood is 100% renewable and therefore a unique building material. By using wood instead of non-renewable materials, we significantly reduce the negative human impact on the environment. Contact with nature is also a source of creativity and inspiration. A person can enjoy nature in different ways: someone is inspired by walks in the fresh air, for someone the contemplation of a majestic forest is valuable. In NUMO wooden houses there is another way to enjoy nature without even leaving your home.

Wood has the unique ability to absorb moisture and release it as the room dries. This “breathing” function ensures that the house will create optimal conditions for your health. By choosing NUMO, you are choosing a home built without the use of any synthetic insulation materials or vapor barriers. Our homes are plastic-free – natural and clean wood surrounds you, helping you to calm down after a long day at work, reduce your overall stress level and improve your sleep quality.

Each NUMO home has a subtle aroma of coniferous forest. It is impossible not to agree that this pleasant and fresh smell improves the quality of everyday life in the house dozens of times. You have certainly experienced the soothing atmosphere of a pine forest. Now imagine that you get the same feeling every day, just by being in your home. In addition to a pleasant aroma, wood is aesthetically beautiful and pleasant to the touch. All this creates a unique calming atmosphere, which is so important to have at home.

Sample projects numo

A wooden house made of timber that breathes with you

Timber has established itself as an excellent energy-efficient building material. Being resistant to temperature extremes, a glulam house stays cool in summer and retains heat in winter.

Our timber is impregnated with Remmers antibacterial and antimicrobial compounds.

This protects the manufactured houses from moisture, fungi and various insects, thereby increasing their service life.

With an increase in moisture in the air, the pine absorbs it, and with a decrease, on the contrary, it releases it. This “breathability” ensures that the humidity level is optimal for human health.

Reliable and durable wooden houses

A wooden house can stand for hundreds of years. Glulam houses are resistant to various adverse weather conditions, including snowfalls and strong winds. The snow load on the flat roof of a NUMO house allows for more than 300 kg/m2, which is equivalent to a “snow cap” 6 meters high. Wooden houses, due to the strength of wood and horizontal construction, are the safest option in areas prone to earthquakes.

Our houses use the latest technology of nodal wall connection. With increased comfort from living in a wooden house, the level of energy consumption remains unusually low. Glulam wall is a natural insulator with high heat capacity, NUMO house wall accumulates heat. There are so-called “energy efficient” models in the NUMO line of houses. The walls of such houses are glued beams with internal insulation.

In general, wood is a combustible material, but in construction, glued laminated timber is considered to be extremely fire resistant. Good fire resistance of wood is the result of its properties: natural moisture protects against ignition. Electrical wiring is implemented without the use of junction boxes. In addition, all wiring in the walls and under the floors is carried out in metal pipes that do not support combustion.

|

|

|

|

| Our Modular House | 6,8 | 13 TONS | 3 days |

| Glued beam house | 3 | 15 TONS | 1.5 -4 months |

| Frame house | 4 | 7 TONS | 1.5 – 2 months |

Our houses are mobile and can be installed

anywhere in the world

Integrated construction

Complex works implemented by our company

Choice of timber

When selecting timber, we take into account the local climate and local building regulations, as well as the personal preferences of the client. Our range includes timber of various sections. Additionally, we offer glued laminated timber with insulation, which makes the house even warmer and more energy efficient.

Houses made of glued beams meet modern energy saving requirements for residential buildings today. For each NUMO house, we carefully select timber that will meet the needs of this particular building in the given climatic zones.

In NUMO houses, the customer can choose not only the cross-section of the timber and the presence of insulation, but also the grade of the timber itself: first or zero. The lumber of the first grade can be supplied with only healthy knots.

The bar of a zero grade is characterized by the highest quality of processing. When gluing such a beam, lamellas with knots are not used. This type of wood is commonly used in aircraft and shipbuilding.

Prefabricated houses

The first stage in construction is the assembly of the house kit. We deliver the house kit to the place where the house is being built, we install walls and roofs, install doors and windows, and install a storm system. After this stage, the house is completely ready for interior decoration.

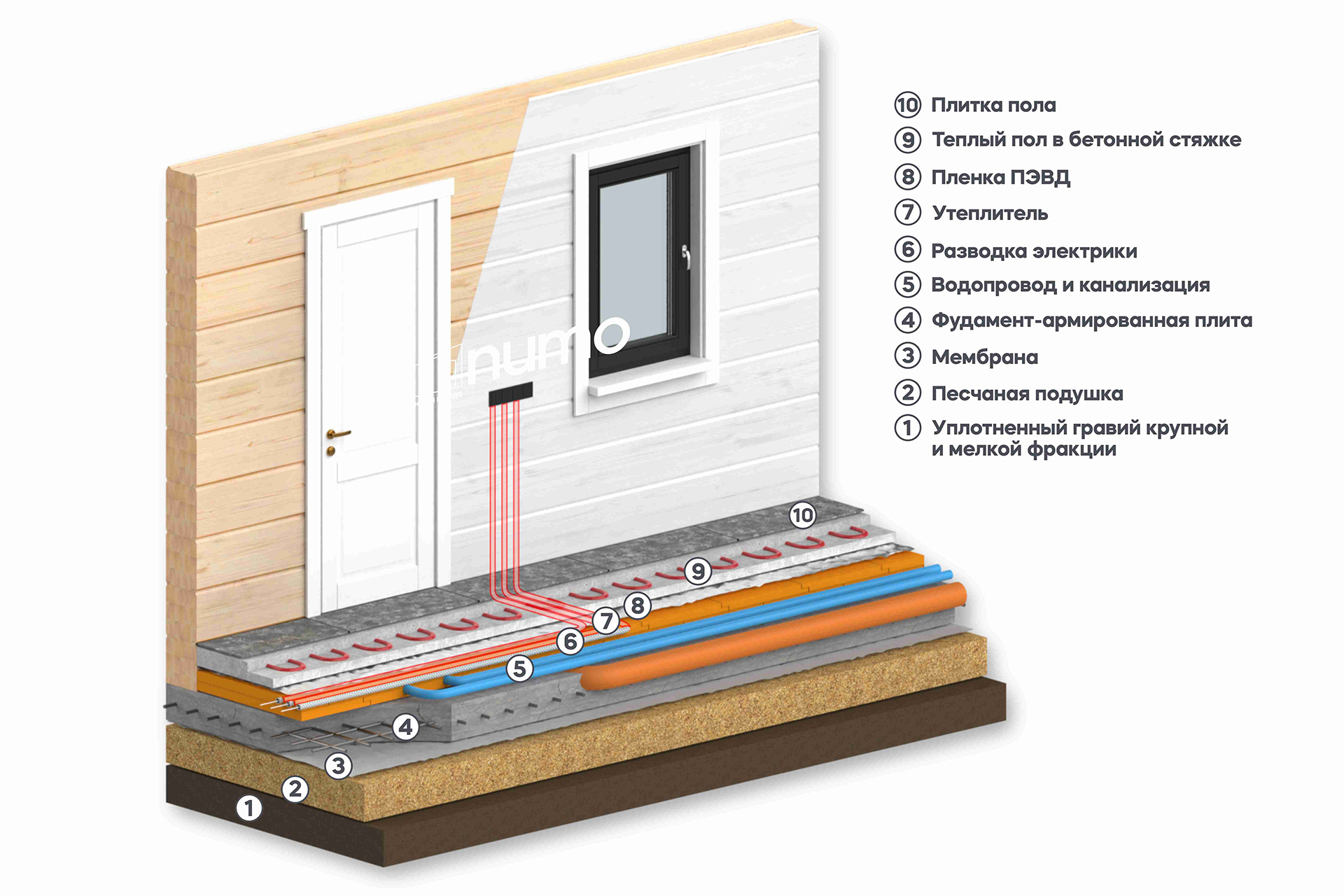

Next, we proceed to the installation of engineering networks: water supply, sewerage, electricity, heating and video surveillance. We carry out interior wall painting, installation of the finishing ceiling, laying tiles, installing interior doors, installing sockets and switches.

Our company completes the object with furniture. We will develop the interior design of your home, select materials and fittings, produce high-quality furniture and deliver it together with the house kit. Let’s install furniture, we will mount the sanitary equipment.