Do you want to change the layout?

The houses are completely made in our production, which guarantees the impeccable quality of materials, painting

and durability of all modules

What is included in the turnkey price?

Topographic survey is a complex of engineering and geodetic works for measuring a piece of terrain and entering data on the features of the relief, the position of all objects and the distance between them into a topographic plan

- Geological surveys are a whole group of studies aimed at determining the geological and hydrogeological conditions on the site planned for the construction of a private house.

- A set of measures is represented not only by field tests on the ground, but also by laboratory, cameral analyzes, and forecasting regarding the development of dangerous geological processes under the influence of natural and anthropogenic factors.

- The study is carried out by drilling 3 wells 8 meters deep with soil sampling. The selected soil undergoes laboratory studies of physical and mechanical properties, and a report is compiled based on the results of the studies, which is used in calculating the bearing capacity of the foundation.

RCP project (Reinforced concrete structures):

- Calculation of static loads on the foundation in the SKAD program.

- Development of a RCP project in Autocad.

- Binding axes together with the customer, drawing up an act of binding.

- Associating the zero point with the customer.

- Checking the red lines in the parcel. Coordination with the cottage settlement (if required).

- Photo fixation of the binding in your account.

Selection and verification of RBU (mortar-concrete unit) according to checklists and geography:

- Having our own laboratory, laboratory assistants, non-expired verification of laboratory equipment.

- Checking financial statements.

- Checking if you have your own mixer fleet.

- Checking the quality passport of the 1st cat. according to GOST 7473-2010 with all items filled in.

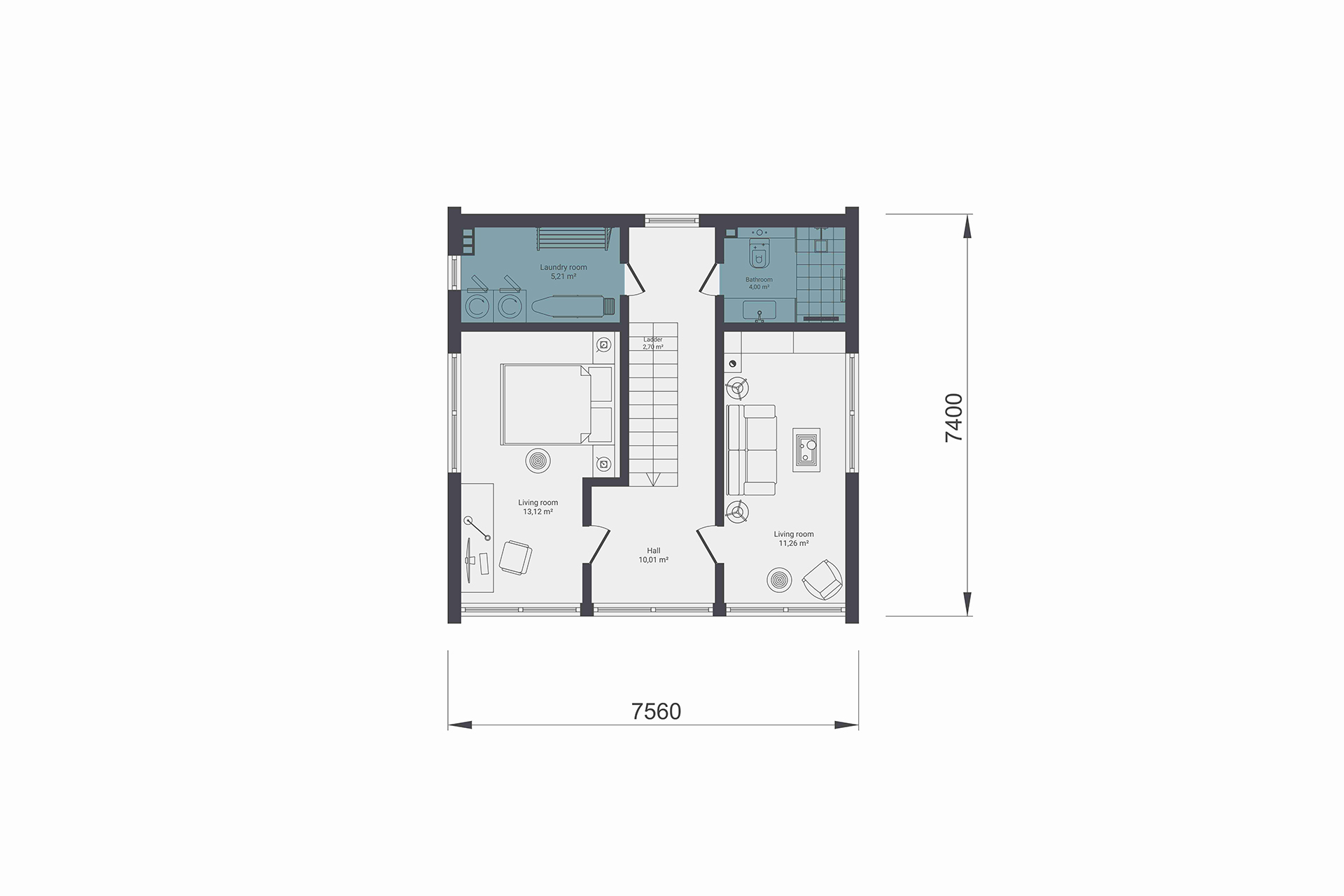

The composition of the working draft CD (Wooden Structures) includes:

- Wall set:

- General instructions.

- Isometric views.

- Floor plans.

- Plan of the 0th crown.

- Beam plans and beam layouts across all floors.

- Walls.

- A set of nodes (more than 700 unique technical solutions).

- Open the beams.

- Detailed layout of the material (scattering).

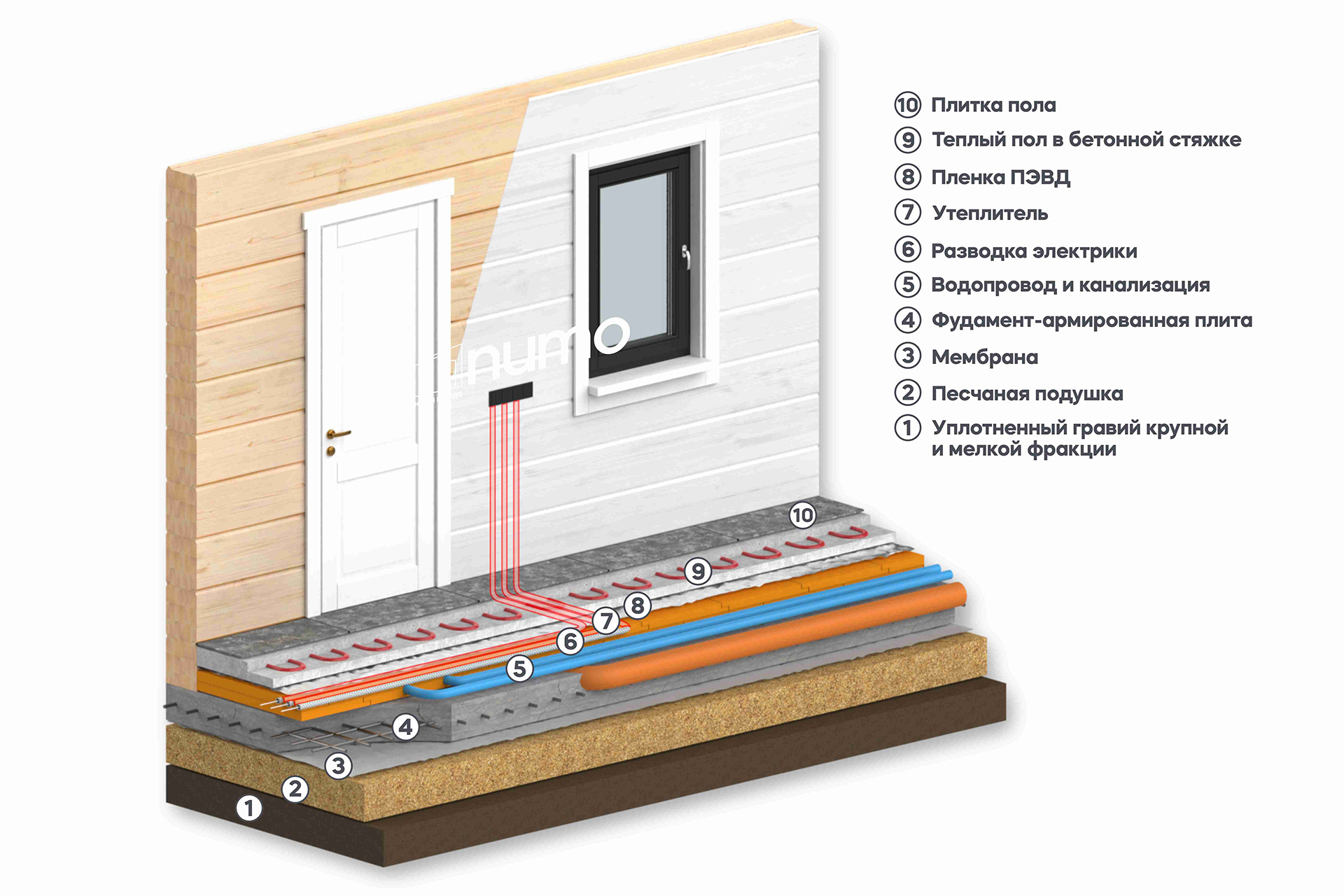

To protect the lower crown from decay between the foundation and the lower crown of the beam, we lay a larch lining board. Larch has a denser wood, it is not afraid of water and isolates the lower crown from getting wet.

Glued wall beam of our own production, section 240х293(h), mm

- The thickness of the double-glazed window is 40 mm.

- Multifunctional coating on the outer glass protects from the sun in summer, keeps warm in winter (Solar).

- Low-E coating on the inner glass – additional protection to retain heat (LowE).

- Chromatech Ultra composite spacer with improved thermal insulation to prevent condensation on the glass

- Two chambers filled with argon give the lowest thermal conductivity (Ar).

- The reduced heat transfer resistance of the window (together with the profile) R=0.92 sq.m* C/W.

Topographic survey is a complex of engineering and geodetic works for measuring a piece of terrain and entering data on the features of the relief, the position of all objects and the distance between them into a topographic plan

Choice of timber

When selecting timber, we take into account the local climate and local building regulations, as well as the personal preferences of the client. Our range includes timber of various sections. Additionally, we offer glued laminated timber with insulation, which makes the house even warmer and more energy efficient.

Houses made of glued beams meet modern energy saving requirements for residential buildings today. For each NUMO house, we carefully select timber that will meet the needs of this particular building in the given climatic zones.

In NUMO houses, the customer can choose not only the cross-section of the timber and the presence of insulation, but also the grade of the timber itself: first or zero. The lumber of the first grade can be supplied with only healthy knots.

The bar of a zero grade is characterized by the highest quality of processing. When gluing such a beam, lamellas with knots are not used. This type of wood is commonly used in aircraft and shipbuilding.

Will this project fit on my lot?

The houses are completely made in our production, which guarantees the impeccable quality of materials, painting

and durability of all modules

Prefabricated houses

The first stage in construction is the assembly of the house kit. We deliver the house kit to the place where the house is being built, we install walls and roofs, install doors and windows, and install a storm system. After this stage, the house is completely ready for interior decoration.

Next, we proceed to the installation of engineering networks: water supply, sewerage, electricity, heating and video surveillance. We carry out interior wall painting, installation of the finishing ceiling, laying tiles, installing interior doors, installing sockets and switches.

Our company completes the object with furniture. We will develop the interior design of your home, select materials and fittings, produce high-quality furniture and deliver it together with the house kit. Let’s install furniture, we will mount the sanitary equipment.

All materials used are of premium quality.

Completed projects

Completed projects

Interior decoration of the house

Comparison of construction technology

|

|

|

|

| Our modular house | 6,8 | 13 tons | 3 days |

| glued timber house | 3 | 15 tons | 1,5 - 4 months |

| frame house | 4 | 7 tons | 1,5 - 2 months |

Featured Projects

Featured Projects

Get a specialist consultation

The houses are completely made in our production, which guarantees the impeccable quality of materials,

painting and durability of all modules